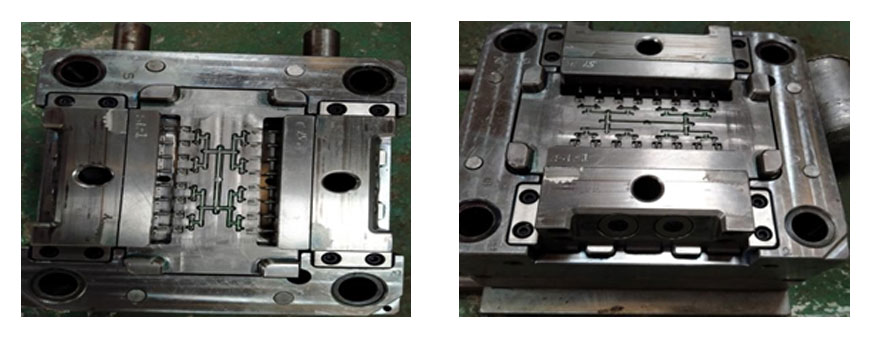

NUT PLASTIC 16 CAVITY MOULD

The Nut Plastic 16 Cavity Mould is a high-performance injection mould designed to produce plastic nuts with exceptional dimensional precision and consistent quality. Engineered using hardened tool steel and state-of-the-art CNC machining, this mould ensures long production life, reduced cycle times, and minimal parting line mismatch.

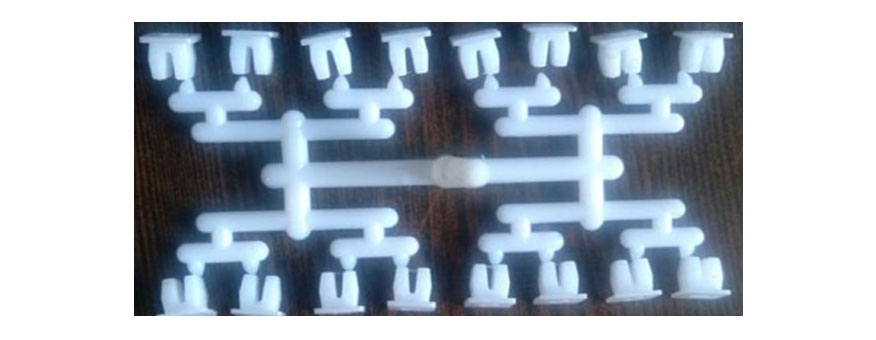

With 16 identical cavities, this mould significantly boosts productivity in mass manufacturing environments, making it ideal for high-volume OEM and industrial applications. Its advanced cooling channel design promotes uniform cooling and minimized warpage, resulting in excellent part consistency.

The mould is built with precision alignment features, superior surface finishing, and interchangeable inserts to simplify maintenance. It supports a variety of plastic materials such as PP, ABS, and Nylon, meeting diverse client specifications with ease.

Key Mould Features

This 16 cavity mould delivers reliable performance for continuous production, making it a trusted tool in industries requiring fast output and consistent quality.

Precision Machined Tool Steel Cavities

Engineered for high durability and accuracy in mass production.

High Production Efficiency

Uniform cavity filling boosts output with fewer rejects.

Optimized Cooling System

Reduces cycle time and enhances mould lifespan.

Supports Various Resins

Compatible with engineering-grade plastics like PP, ABS, Nylon, etc.

Why Choose This Mould?

Our Nut Plastic 16 Cavity Mould ensures superior durability, output consistency, and fast ROI. It's custom-designed to meet your specific component requirements and can be integrated seamlessly into your injection moulding workflow. Whether for automotive, electrical, or general industrial use, this mould guarantees quality and productivity at scale.