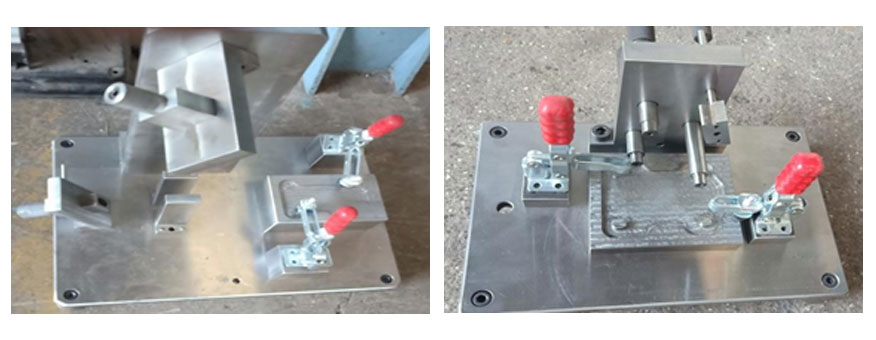

INTRA PBL ASSLY CHECKING FIXTURE

The INTRA PBL Assly Checking Fixture is an advanced precision-engineered setup used to inspect and validate the dimensional and positional accuracy of PBL (Printed Back Label) assemblies in automotive and industrial applications. This fixture ensures every component is assembled as per design tolerances and specifications, helping maintain consistent quality standards.

Developed using robust base materials with hardened steel contact points, the fixture offers stability, longevity, and high repeatability. It is designed to be operator-friendly, ensuring quick loading and unloading, minimal maintenance, and efficient inspection processes on the shop floor.

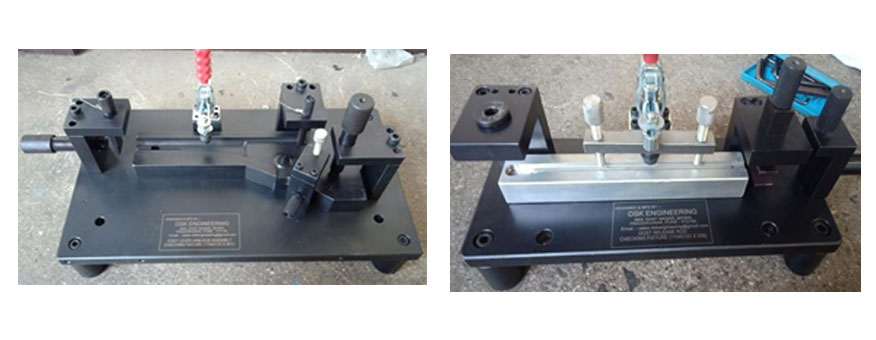

The fixture can be integrated into both manual and semi-automated inspection stations. It is compatible with gauges, dial indicators, and limit blocks, ensuring thorough verification of the PBL assembly before final dispatch or next-level integration.

Key Inspection Workflow

The fixture allows systematic checking of all critical parameters of the PBL assembly to ensure functional and aesthetic compliance with design intent. It facilitates quality checks at the intermediate and final stages of assembly.

- Checks profile, slots, and mounting hole positions

- Ensures correct orientation and fitment

- Compatible with Go/No-Go gauges and visual checks

- Robust build suitable for repeated inspections

- Reduces human error and inspection time

Why Choose This Fixture?

Our INTRA PBL Assly Checking Fixture is designed to improve inspection accuracy and streamline production. With quick-clamp systems, ergonomic handles, and accurate locating pins, it minimizes downtime and enhances throughput. We customize each fixture to suit your part geometry, inspection criteria, and operational workflow — making it a trusted tool for OEMs and Tier 1 suppliers.