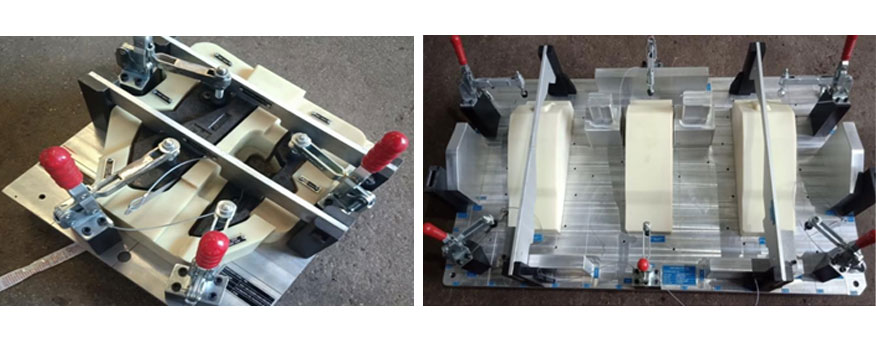

FOAM COMPONENT CHECKING FIXTURE

The Foam Component Checking Fixture is a specialized inspection fixture designed to verify the shape, contour, and critical dimensions of foam-based automotive or industrial components. It helps ensure that foam parts are molded and trimmed precisely to meet the functional and aesthetic standards required for final assembly.

Constructed using durable aluminum or fabricated bases with precision-machined contact profiles, this fixture allows accurate and repeatable inspection for soft or compressible foam materials. Its lightweight yet rigid structure supports ergonomic handling on the shop floor and in quality labs.

The fixture can be integrated into manual quality checkpoints or semi-automated systems and supports visual, tactile, and Go/No-Go verification. It's ideal for seat foams, NVH pads, insulation blocks, and interior trim foam parts.

Key Inspection Workflow

The fixture enables detailed verification of part geometry, symmetry, and dimensional tolerances — especially for components prone to deformation or variation during molding and trimming.

- Verifies profile, cutouts, and trim accuracy.

- Supports Go/No-Go and visual template checks.

- Designed for soft material interaction without damage

- Lightweight and easy to handle by operators.

- Reduces inspection variability and improves quality.

Why Choose This Fixture?

Our Foam Component Checking Fixtures are built to optimize the accuracy and consistency of quality inspection. They are tailored for your specific foam component shape and functional zones. With modular add-ons, ergonomic clamping, and reliable reference surfaces, this fixture ensures smooth inspection with minimal cycle time — making it a vital tool in foam part validation across automotive and manufacturing domains.